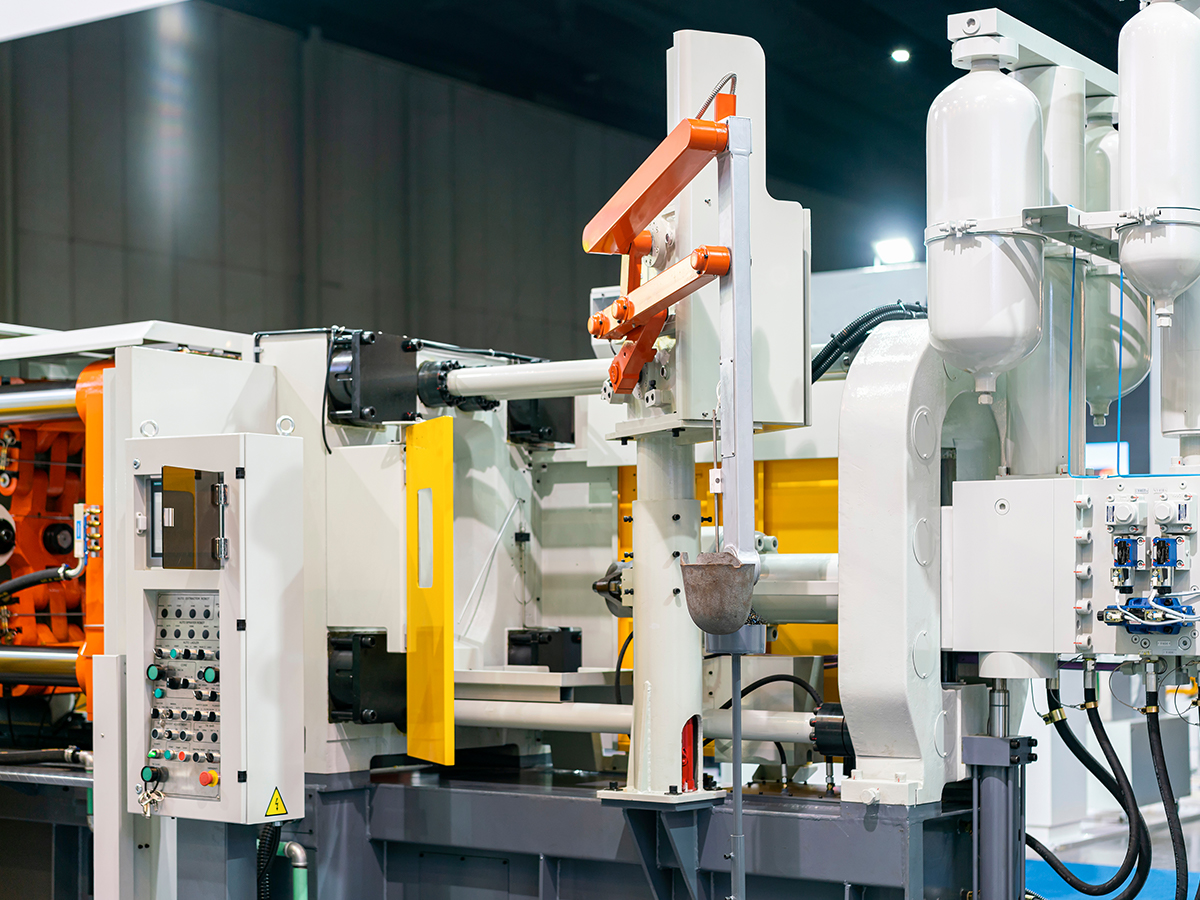

Die Casting Lubricants

Fluid Solutions is capable of providing all lubrication requirements from Die Casting Machine Lubrication to process fluids such as release agents to the hydraulic fluids to operate the machine.

Die Cast Machine Lubrication

Die Cast Release Agents

Plunger Lubricants

Auxiliary Lubricants and Coating

Frequently Asked Questions

What are die casting lubricants?

Die casting lubricants are specialized substances applied to molds to facilitate the release of castings. They improve the flow of molten metal, reduce friction between the mold and the casting, and enhance the overall efficiency of the die casting process.

What are die casting lubricants used for?

Die casting lubricants are used to improve mold release, reduce wear and tear on dies, enhance the quality of the castings, and increase the overall efficiency of the die casting process.

What are die casting lubricants made of?

Die casting lubricants are formulated with a variety of components, including lubricating oils, additives, and sometimes water-based substances. These formulations are designed to meet the specific needs of the die casting process while ensuring environmental and operator safety.

What are examples of die casting products?

Die casting is commonly used to produce a wide range of products, including automotive parts, consumer electronics, appliance components, and industrial equipment.

What are die cast components?

Die cast components refer to the parts manufactured through the die casting process. These components are known for their precise dimensions, excellent surface finish, and high strength.

What is the most suitable material for die casting?

Aluminum, zinc, and magnesium alloys are popular materials for die casting due to their excellent casting properties, lightweight nature, and high strength.

What material is commonly used in casting?

Die casting commonly uses non-ferrous metals, such as aluminum, zinc, and magnesium, due to their exceptional casting characteristics and mechanical properties.