High-temperature greases are specialized lubricants designed to withstand extreme heat while maintaining their consistency, lubricating properties, and protective capabilities.

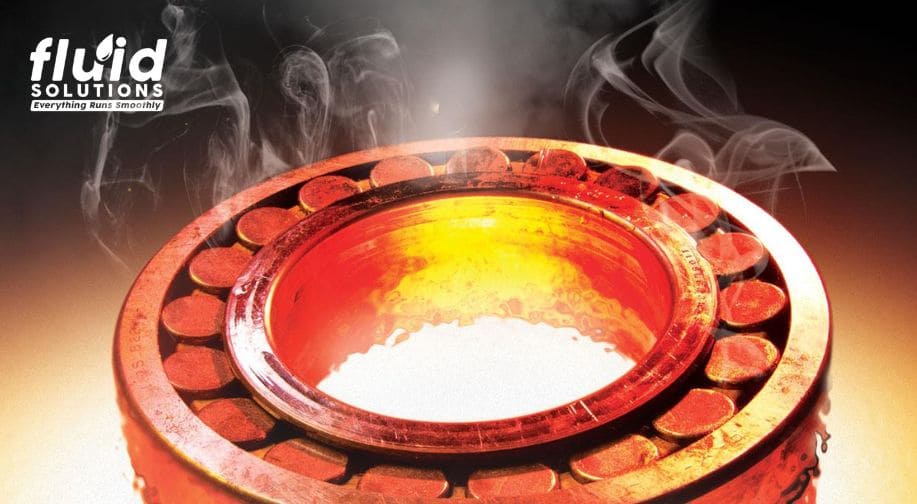

Choosing the right high-temperature greases is crucial for ensuring optimal performance and longevity of machinery in extreme conditions. Lubrication failures can lead to increased wear, equipment breakdowns, and costly downtimes. Among the most used high-temperature greases are silicone-based and PTFE-based formulations, each offering distinct advantages depending on the applications. Understanding their differences will help industries make informed decisions to maximize efficiency and reliability.

Key Takeaways:

- Silicone greases are best for high temperatures, moisture, and plastic/rubber compatibility.

- PTFE greases are ideal for high temperatures, heavy loads, friction, and chemical resistance.

- Silicone greases suit electrical parts and seals, PTFE greases fit bearings, gears, and metal contact.

- Choose based on temperature, pressure, and material compatibility.

What are Silicone-Based High-Temperature Greases?

Silicone-based high-temperature greases are formulated using synthetic silicone fluids combined with a thickener. This type of grease is widely known for its exceptional thermal stability, allowing it to perform well under extreme temperatures without breaking down or losing effectiveness.

One of the key advantages of silicone greases is their oxidation resistance, which prevents them from hardening or degrading over time, even in continuous high-temperature applications. They exhibit excellent water resistance, making them ideal choices for environments exposed to moisture or humidity. Because of their excellent compatibility with rubber and plastic components, silicone-based greases are often used in electrical insulations and delicate machine components that require lifetime lubrication without damaging non-metal materials.

Silicone greases are widely used in applications such as:

- Electrical components requiring insulation and moisture protection

- Food processing equipment where FDA-approved greases are necessary

- Rubber and plastic parts that require long-lasting lubrication

What are PTFE-Based High-Temperature Greases?

PTFE-based high-temperature greases incorporate polytetrafluoroethylene (PTFE), a synthetic fluoropolymer that provides outstanding lubrication properties. Known for their extreme pressure resistance and low friction coefficient, PTFE-based greases are ideal for high-load applications where metal-to-metal contact occurs frequently.

Besides its superior friction-reducing capabilities, PTFE greases offer excellent chemical resistance, allowing it to withstand exposure to harsh solvents, acids, and aggressive environments. This makes PTFE lubricant greases the preferred choice in aerospace, automotive, and heavy industrial settings where machinery operates under intense pressure and fluctuating temperatures. Bearings, gears, and high-speed components particularly benefit from PTFE-based greases as they ensure smooth operation and prolong equipment life.

Common applications of PTFE-based greases include the following:

- Bearings, gears, and sliding mechanisms in heavy machinery

- Aerospace components exposed to high friction and extreme conditions

- Industrial equipment operating in chemically aggressive environments

Key Differences Between Silicone-Based and PTFE-Based High-Temperature Greases

While both types of high-temperature greases provide effective lubrication, they differ significantly in their properties and applications.

Silicone-based greases excel in thermal stability, maintaining consistent performance across a wide temperature range. They resist oxidation and remain effective even in extreme heat or cold, making them ideal for applications that require long-term lubrication without frequent reapplication. It is also highly compatible with rubber and plastic materials, preventing degradation that might occur with petroleum-based lubricants. However, silicone-based lubricants are not well-suited for high-load applications, as they do not provide the same level of extreme pressure resistance as PTFE grease.

While PTFE greases perform at elevated temperatures, they are also formulated for applications that require superior friction reduction and wear protection. They perform exceptionally well under heavy loads, making it a preferred choice for bearings, gears, and sliding mechanisms. PTFE greases also exhibit outstanding chemical resistance, making them ideal for environments exposed to solvents, acids, and aggressive industrial chemicals. However, it may not be as effective as silicone greases in extreme temperature conditions, where oxidation stability is critical.

Silicone greases are also preferred in applications where compatibility with sensitive materials (such as plastics and rubber) is essential, while PTFE greases are chosen for their ability to withstand mechanical stress and provide long-lasting protection under load.

Ultimately, the choice between silicone and PTFE greases depends on factors such as operating temperature, load conditions, and material compatibility. Each type offers unique benefits that cater to specific industrial requirements.

Get Expert Lubrication Solutions from Fluid Solutions

Fluid Solutions Inc. offers a comprehensive range of high-performance lubricants, including premium silicone-based and PTFE-based high-temperature greases. With years of expertise in industrial lubrication, we provide tailored solutions to meet the specific needs of businesses across various industries.

Our product offerings include:

- Advanced Lubrication Solutions – A diverse selection of high-temperature greases designed for different industrial applications.

- Industry-Specific Recommendations – Expert guidance on selecting the best greases for your equipment and operating conditions.

- Reliable Supply & Support – High-quality lubrication products backed by exceptional customer service.

Ensure your machinery operates at peak efficiency with the right high-temperature grease. Contact Fluid Solutions Inc. today for expert recommendations and premium lubrication products.

Call (02) 8370 5928 / (0917) 894 9156 or email us at inquiry@fluidsolutions.com.ph to learn more about our lubrication solutions.

Social Media Links:

Facebook: https://www.facebook.com/fluidsolutionsinc

LinkedIn: https://www.linkedin.com/company/fluid-solutions-inc