Source: https://cwgr.co.za/wp-content/uploads/2021/06/industrial-gearbox-issues-980×651.jpeg

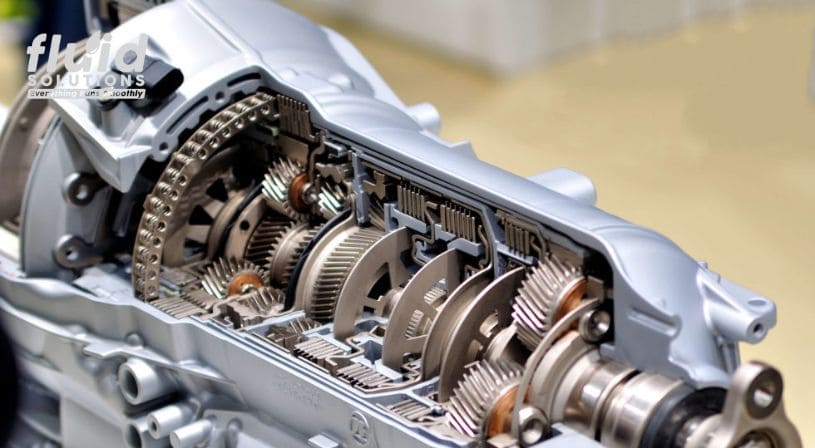

Effective lubrication is essential for maintaining the condition of gearboxes. Proper gear oil lubrication prevents friction between moving components, reducing wear, preventing overheating, and avoiding system failures.

The lubrication method used in your gearbox will depend on several factors, including the type of gearbox, operating conditions, and load requirements. There are different gearbox lubrication methods available, such as splash lubrication systems, mist lubrication systems, and forced circulation systems. Each method presents unique advantages and challenges, which will be examined in greater detail.

Splash/Bath Lubrication Systems

A. Description

The splash gear oil lubrication system is one of the simplest and most cost-effective methods for lubricating gearboxes. In this system, gears dip into a reservoir of gear oil. As the gears rotate, they splash the oil onto surrounding components, providing necessary lubrication.

B. Applications

A splash gear oil lubrication system is most effective when used in gearboxes that operate at low to moderate speeds. The system relies on the motion of the gears to splash oil into all necessary parts, making it ideal for small-to-medium-sized industrial gearboxes. It is particularly effective for applications where the load is not excessively high and the operational speeds are within reasonable limits.

C. Pros

- Simple and Low Maintenance: The splash lubrication system is relatively easy to maintain, with minimal parts that need regular attention.

- Cost-Effective: Compared to more complex lubrication systems, splash lubrication requires less investment in equipment, and maintenance costs are generally lower.

D. Cons

- Limited Cooling and Reach at Higher Speeds: One of the main limitations of the splash lubrication system is that it may struggle to provide adequate cooling and lubrication at higher speeds. This can be challenging in systems where high-speed gearboxes are required.

- Risk of Oil Starvation: If the system is not properly maintained or the gear oil level drops too low, there is a risk of oil starvation, leading to premature wear and failure of gearbox components.

Forced Circulation Systems

A. Description

A forced circulation lubrication system involves the use of an external pump to continuously circulate gear oil throughout the gearbox. This system ensures a consistent and controlled flow of oil, providing lubrication even at high speeds and under heavy loads. The pump pushes the gear oil through the system, and filters may be used to ensure the oil remains clean.

B. Applications

Forced circulation lubrication systems are best suited for high-speed gearboxes or gearboxes under heavy load conditions. These systems are often found in large industrial machinery, such as that used in the automotive, mining, and manufacturing industries, where precise lubrication is essential for efficient performance.

C. Pros

- Controlled Flow and Temperature: A forced circulation system allows for better control of gear oil flow and temperature, which improves the performance and longevity of gearbox components.

- Improved Filtration and Oil Cleanliness: This system typically includes a filtration system that helps maintain gear oil cleanliness, extending the life of the lubricant and the gearbox.

D. Cons

- Higher Cost and System Complexity: Compared to simpler lubrication systems like splash lubrication, forced circulation systems are more complex and costly to install and maintain.

- Requires Ongoing Monitoring and Maintenance: Due to the complexity of the system, regular monitoring is required to ensure the pump and filtration systems are functioning properly.

Mist and Spray Applications

A. Description

Mist and spray lubrication systems are often used in gearboxes that require precise and efficient lubrication, particularly in environments where conventional methods like splash lubrication systems might not be effective. In a mist lubrication system, gear oil is atomized into small droplets, which are then dispersed over the components that need lubrication. In a spray lubrication system, gear oil is sprayed directly onto components using nozzles or jets.

B. Applications

Mist and spray lubrication systems are ideal for use in high-speed gearboxes and enclosed gearboxes that need precise oil delivery. Applications include industries such as aerospace, automotive, and other purposes where consistent and precise lubrication is critical.

C. Pros

- Efficient Oil Use: One of the main advantages of mist and spray lubrication is the efficient use of gear oil. Because the oil is atomized or sprayed directly onto components, oil consumption is highly efficient, making it a more sustainable lubrication method.

- Ideal for Hard-to-Reach Areas: In compact or enclosed gearboxes, the ability to directly spray oil onto components helps ensure all areas are adequately lubricated, especially in precision gears that might be difficult to access with traditional lubrication methods.

D. Cons

- Requires Precision: Mist and spray lubrication systems need to be carefully calibrated to ensure the right amount of gear oil is delivered to each component. If the system is not correctly adjusted, it could result in under-lubrication or over-lubrication, which could lead to inefficiency or oil waste.

- Sensitive to Pressure and Contamination: The performance of mist and spray systems can be impacted by variations in pressure and contamination in the air or oil. For optimal performance, the gear oil must be free from debris and impurities, and the system must be maintained to prevent pressure fluctuations.

Protect Your Equipment with Expert Lubrication Support from Fluid Solutions

Selecting the right gear oil and lubrication method is critical to the health of your gearboxes. At Fluid Solutions, we offer expert recommendations based on your specific gearbox type, application, and operating conditions. Whether you’re looking for the best gear oil for your high-speed gearboxes or need advice on choosing between gear lubrication systems, we are here to help.

By working with our experts, you’ll benefit from improved performance and reliability, reduced downtime, and lower maintenance costs. Contact Fluid Solutions today to speak with a lubrication expert and find the ideal lubrication solution for your operations’ needs.

Social Media Links:

Facebook:https://www.facebook.com/fluidsolutionsinc

LinkedIn: https://www.linkedin.com/company/fluid-solutions-inc