Maintaining the efficiency and longevity of your electrical motors is crucial in the industrial sector. Regular motor maintenance, particularly regreasing, helps prevent unexpected breakdowns, preventing the interruption of the entire manufacturing process.

Neglecting lubrication can lead to overheating, worn bearings, and, eventually, motor failure. In this guide, we’ll walk you through the essential steps for regreasing an electrical motor to keep it running at peak performance.

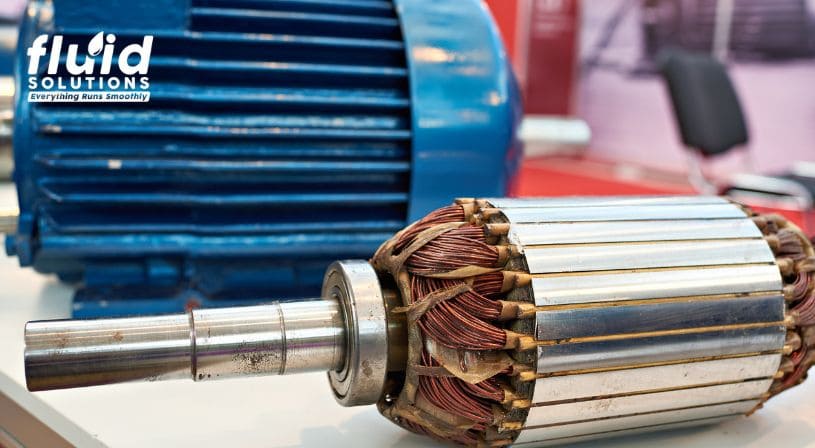

Tools and Materials Needed for Regreasing

Image Source: https://www.istockphoto.com/photo/rotor-with-copper-winding-electric-motor-gm802862690-130169851

Before starting the regreasing process, the following items are necessary for a successful regreasing:

- Grease gun: Used to apply the lubricant precisely.

- Electrical motor grease: High-quality grease specifically designed for motor bearings.

- Cleaning clothes or rags: Essential for wiping away old grease, dirt, and debris, ensuring a clean surface for new lubricant application.

- Screwdriver or other tools: Needed to access motor bearings and remove any protective covers.

- Grease fitting cleaner: Helps clean fittings to prevent contamination of new grease.

- Protective gear: Gloves and safety glasses for personal protection, preventing accidental grease contact or injuries.

Having all the right tools ensures the process is not only effective but also safe. By preparing properly, you minimize the risk of contamination, equipment damage, or personal injury, ensuring the electrical motor operates efficiently for longer.

Step-by-Step Regreasing Procedure

Follow these detailed steps to regrease an electrical motor effectively.

Step 1: Preparing the Motor

Before starting, ensure the motor is powered off and disconnected from its electrical supply to avoid accidents. If it’s been in operation, allow the motor to cool down. Proper preparation ensures safety and improves the lubrication process’s effectiveness.

Step 2: Cleaning the Grease Fittings

To prevent contamination, grease fittings must be cleaned before new grease is applied. Use a grease fitting cleaner and wipe away any old grease, dirt, or debris with a clean cloth. This step ensures no contaminants are introduced into the motor bearings.

Step 3: Applying the Correct Grease

Select the type of grease recommended for your motor type—typically a high-temperature, high-quality electric motor grease. Using a grease gun, apply the proper amount of grease. Be careful not to overfill, as too much grease can cause bearing overheating and reduce motor efficiency.

Step 4: Regreasing the Motor Bearings

Next, the grease is injected directly into the motor bearings via the grease fittings. Distribute the grease evenly to ensure full coverage and prevent bearing wear. This step is crucial for maintaining the motor’s longevity.

To avoid contamination, use clean tools and gloves during the application process.

Step 5: Post-Regreasing Checks

After regreasing, it’s essential to check the motor for proper operation. Run the motor and listen for any unusual noises or vibrations, which could show uneven grease distribution or potential mechanical issues. Verify that the grease is properly seated in the bearings to ensure smooth operation.

Performing these post-maintenance checks helps guarantee that the motor will run efficiently after lubrication.

Common Mistakes to Avoid During Regreasing

Even with the best tools and materials, some common mistakes can undermine your efforts to regrease the motor properly:

- Over-greasing: While lubrication is critical, excessive grease or oil can damage the motor.

- Using the wrong grease: It’s important to select grease that is compatible with your motor and operating environment. Always consult the motor manufacturer or use electric motor grease from a trusted supplier like Fluid Solutions.

- Skipping cleaning: Failing to clean grease fittings before applying new grease can introduce contaminants that reduce bearing life.

By avoiding these pitfalls, you can ensure that your motor remains in good working condition.

Explore Fluid Solutions’ lineup of Multipurpose and EP Greases for high-quality lubrication solutions.

Maximize Your Motor’s Lifespan with High-Quality Greases from Fluid Solutions

Enhance your motor’s performance and longevity with premium grease solutions from Fluid Solutions. With over 16 years of industry experience, we provide high-quality electric motor greases designed for optimal performance and compliance.

Visit our Contact Us page today to speak with our experts or explore our extensive range of lubrication solutions tailored to your specific industry needs. Whether you’re looking for high-performance grease for motors or specialized products, we have you covered.

Social Media Links:

Facebook Page: https://www.facebook.com/fluidsolutionsinc

LinkedIn: https://www.linkedin.com/company/fluid-solutions-inc