In industrial machinery and CNC equipment, miniscule, and precise motion of slides, ways, and ball screws are vital to achieving high accuracy. Even the minimal inaccuracies during cutting, drilling, or shaping can impact the quality of the final machined component.

While it is often overlooked, using the right industrial lubricant keeps the motion controlled, reduces wear, and helps maintain the tight tolerances.

What Is the Stick-Slip Phenomenon?

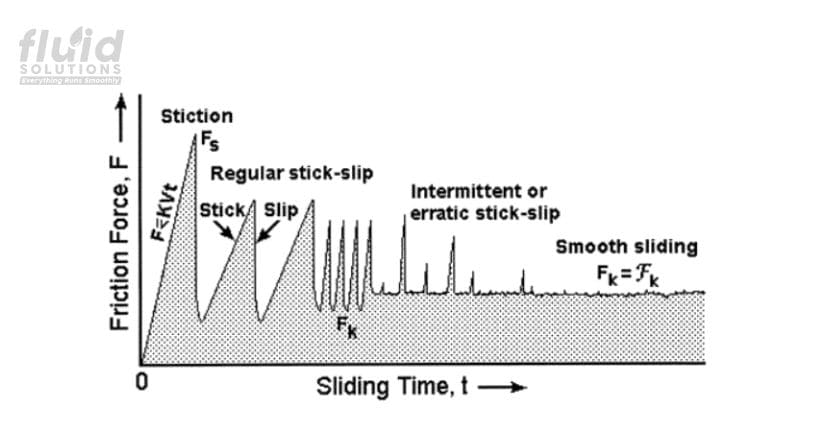

In mechanical systems, signs of stick-slip include uneven or jerky movement, unusual noises, or sudden resistance followed by a quick jump in motion. Failing to address stick-slip can lead to significant issues, including vibrations, uneven motion, chatter marks, and component damage.

What Causes Stick-Slip?

Stick-slip phenomenon occurs when there is a mix of surface friction and adhesion, especially at low speeds. The surfaces stick for a moment because of high static friction, then suddenly slip once enough force builds up, causing abrupt machine motion. The type of material and surface finish also play a part; as rough or uneven surfaces are more prone to sticking. Using an insufficient or inappropriate lubricant increases friction and elevates the risk of stick-slip.

The Role of Slideway Oils in Controlling Stick-Slip

Lubricant manufacturers design slideway oils specifically for machine tool slideways and linear guides. These oils are tacky to stay in place, resist mixing with cutting fluids, and contain anti-wear additives to protect surfaces. These qualities make them ideal for machine tool lubrication, helping reduce stick-slip and keep machine movement smooth and accurate.

Slideway oils form a consistent layer of lubrication film between sliding surfaces. This reduces sudden changes in friction that can cause stick-slip. By maintaining smooth and controlled motion, they support accurate alignment, reduce wear, and boost overall performance in precision equipment.

Applications Where Micro-Movement Control Matters

Whether it is in CNC machining, electronics, or aerospace, subtle movements can significantly impact results. Here is a deep dive where this precision counts, and why it has a significant impact.

- CNC machines and precision milling

Tight control over micro-movements is key to acquiring clean cuts, smooth finishes, and accurate tolerances. Even small motion issues can contribute to surface flaws, noisy tools, or parts that do not meet the required specifications. Whether it is shaping metal or creating detailed molds, consistent, precise movement keeps quality and repeatability at a high level. Proper lubrication plays a significant role, it reduces friction, prevents stick-slip, and keeps motion steady for reliable performance of the machine under tough production demands.

- Metrology and inspection systems

In metrology and inspection systems, controlling micro-movement is key to gaining accurate, repeatable measurements. These tools often depend on sensors or probes that move in tiny steps, thus any sudden or uneven motion can disrupt the results. Whether checking part dimensions, surface finish, or alignment, smooth and precise movement ensures reliable data. Proper lubrication leads to reduced friction and vibration, supporting the elevated level of accuracy necessary in industries like manufacturing, aerospace, and medical device production.

- Robotics and automation platforms

In robotics and automation, precise control of minute movements is key for tasks such as inspection, assembly, or handling delicate parts. Even slight motion errors can affect system precision, causing misalignment, damaging components, or slowing down the process. Robotic arms and actuators function accurately when their movement is smooth and stable, especially in tight spaces or fast-paced setups. Good lubrication helps by reducing friction and preventing abrupt movement, which keeps automated systems operating reliably in industries like electronics, automotive, and high-precision manufacturing.

- Medical and semiconductor manufacturing equipment

Semiconductor and medical device manufacturing equipment needs to move with extreme precision, often at micro or even nano levels. In these fields, even the slightest shift can interfere with a delicate process or affect product quality. Smooth, controlled movement is the key when handling, positioning, or processing tiny parts and materials. As accuracy plays a key role, tight micro-movement control is essential for reliable performance and consistent results.

Protect Your Equipment with Proven Slideway Lubricants

Fluid Solutions offers premium slideway oils that minimize wear, reduce stick-slip, and ensure precise, smooth operation in high-performance equipment. We design our lubricants with exceptional tackiness, anti-wear protection, and compatibility across a variety of machine tool systems to deliver dependable performance.

Selecting the lubricant is important whether you work as an engineer, on a maintenance crew, or in procurement. Examine the slideway oil selection from Fluid Solutions to discover how the correct choice may enhance the precision, longevity, and general operation of your equipment. Contact our experts today at (02) 8370 5928 or (0917) 894 9156 or reach us via email at inquiry@fluidsolutions.com.ph. Check our Facebook and LinkedIn pages for updates and product recommendations.