Beyond just viscosity, lubricant additives such as Anti-Wear (AW) and Extreme Pressure (EP) additives play a crucial role in enhancing lubricant performance. In this comprehensive guide, we delve into the significance of these additives, their mechanisms, selection criteria, and the benefits they offer in industrial applications.

A Glimpse of Anti-wear and Extreme Pressure Additives

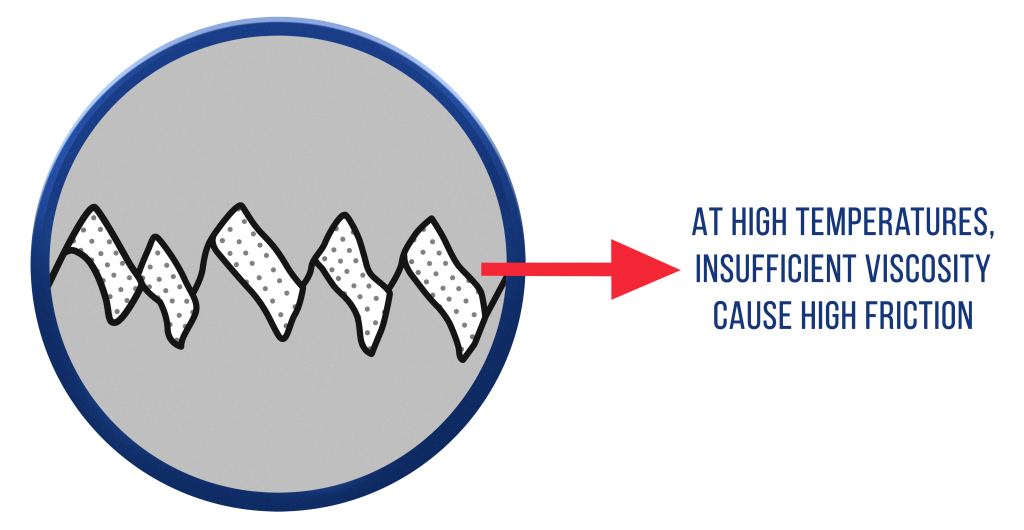

Industrial machinery operates under varying conditions, from high temperatures to heavy loads, making effective lubrication essential for preventing wear and maintaining performance. Ideally, a lubricant’s viscosity should be sufficient to separate two frictional surfaces and prevent wear. However, due to the higher temperatures (or temperature fluctuations) and increased loads of modern machinery, viscosity alone cannot get the job done. Additives that can increase the ‘load-carrying capability’ of a lubricant, preventing gradual wear or catastrophic welding of surfaces, are therefore introduced to most lubricants.

Introducing additives like AW and EP additives can significantly enhance lubricant effectiveness and machinery longevity.

Anti-wear (AW) Additives: Shielding Machinery from Wear

Role and Mechanism

AW additives, as the name suggests, are compounds designed to minimize wear on surfaces in contact. These additives, usually based on fats, zinc, and phosphates form a protective layer, reducing friction and minimizing the impact of regular wear and tear. Such additives are common ingredients in hydraulic oils.

Application and Benefits

AW additives are prevalent in hydraulic oils, where they provide crucial protection against wear in components like pumps and valves. By forming a protective film on metal surfaces, these additives ensure smoother operation and prolonged equipment life.

Extreme Pressure (EP) Additives: Defending Against Intense Pressure

Role and Functionality

EP additives, on the other hand, are designed to withstand and combat the intense pressure and loads experienced by certain machinery components. These additives, usually based on Sulfur and/or Chlorine, form a resilient film under extreme conditions, preventing wear and damage. EP additives are commonly employed in gear systems, metalworking operations, and other heavy-duty industrial applications where extreme pressures are encountered.

Application and Considerations

EP additives are indispensable in heavy-duty industrial applications where extreme pressures are encountered. However, caution is necessary when selecting lubricants with EP additives, especially in environments with softer metals like brass and bronze, where corrosiveness may pose a risk.

Caution in Selecting Lubricants with Extreme Pressure Additives

While EP additives provide crucial protection in demanding environments, caution is warranted when selecting lubricants. In certain applications, such as those involving softer metals or yellow metals like brass and bronze, the use of lubricants with extreme pressure additives can lead to accelerated wear and potential damage. Therefore, it’s imperative to choose lubricants tailored to the specific needs and materials of the machinery in question, ensuring compatibility and optimal performance.

Advancing Machinery Efficiency with Advanced Lubrication Technologies

Performance Enhancement

Incorporating AW and EP additives into lubrication formulations leads to significant performance enhancements, as demonstrated by mechanical load tests like the 4-ball weld and scar tests. These chemical additives contribute to improved machinery efficiency, reduced downtime, and extended service life.

Benefits of Advanced Lubrication

By harnessing the capabilities of AW and EP additives, industries can achieve superior machinery performance and reliability. Advanced lubrication technologies not only protect against wear but also optimize equipment operation, ultimately translating into cost savings and operational efficiency.

Selecting the Right Lubricants: Considerations and Consultation

Factors to Consider

When choosing lubricants with AW and EP additives, factors such as machinery type, operational conditions, and material compatibility must be considered. Selecting the wrong lubricant can lead to accelerated wear and potential damage, underscoring the importance of informed decision-making.

Consultation with Experts

When it comes to navigating the complexities of lubrication, especially with AW and EP additives, it’s wise to seek advice from lubrication experts. These specialists bring valuable insights into your machinery’s unique needs, helping you avoid common issues and get the most out of advanced lubrication practices.

Adding Anti-Wear and Extreme Pressure additives is a game-changer for industries relying on heavy machinery. Beyond just protection, these additives are the key to boosting performance and extending machinery life. To ensure you get the best results, don’t forget to consult with lubrication experts. Their expertise provides personalized recommendations, ensuring your machinery operates at its best for longer.

Partner with Fluid Solutions: The Specialty Lubricants Supplier in the Philippines

The inclusion of anti-wear and extreme-pressure additives is a game-changer for industries relying on heavy machinery. These additives offer crucial protection against wear and damage, enhancing machinery performance and extending service life. To ensure optimal results, consult with lubrication experts like Fluid Solutions, who provide tailored solutions and expert guidance for your oil additives and lubrication needs. Contact Fluid Solutions today at (02) 8370 5928 / (0917) 894 9156 or via email at inquiry@fluidsolutions.com.ph to unlock the full potential of your machinery.