Understanding the intricacies of lubrication science is paramount for optimal performance and longevity. This comprehensive guide explores the critical concepts of viscosity and viscosity index, shedding light on their indispensable roles in machinery operations.

Introduction

Lubricants play a pivotal role in the smooth operation of industrial machinery. Working behind the scenes, lubricants are the secret weapon that keeps your machines running efficiently and prevents overheating. To understand the science of lubrication deeper, it’s crucial to know the properties that define their effectiveness. In this article, we’ll explore viscosity and viscosity index in industrial lubricants.

What is Viscosity?

Viscosity, often referred to as the thickness or resistance to the flow of a fluid, is a fundamental property that influences lubricant performance. It determines how effectively a lubricant can coat and adhere to machinery surfaces, forming a protective barrier against friction and wear.

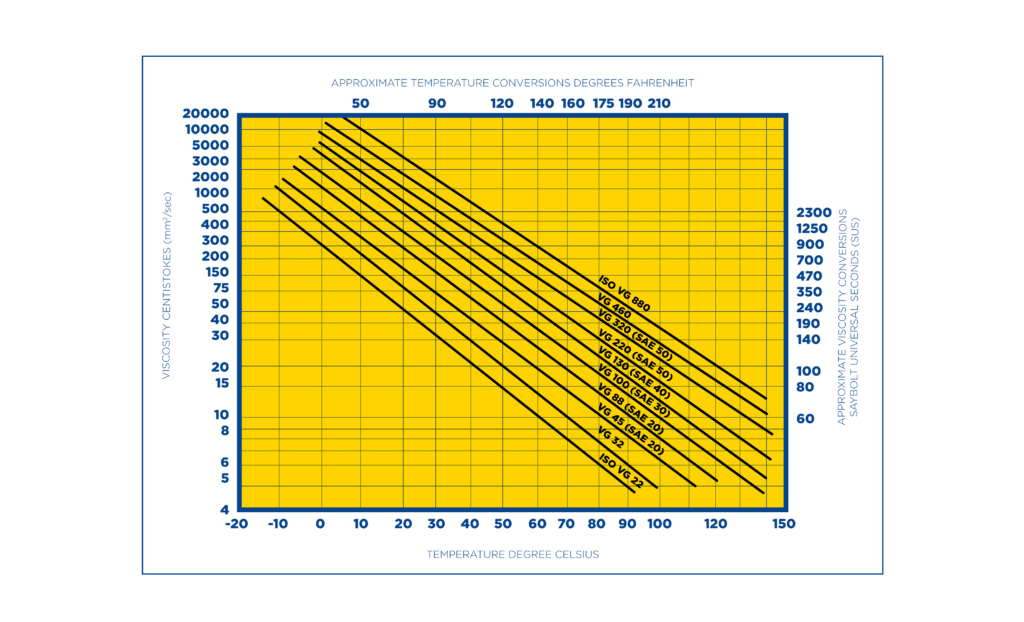

Understanding viscosity is crucial for selecting the right lubricant for specific applications, as it ensures proper lubrication under varying operating conditions. Typically, viscosity measurements are typically expressed in the unit of centistokes (cSt), usually at at 40°C (or mm2/sec).

The International Organization for Standardization (ISO) has established viscosity grade classifications to facilitate lubricant selection. These grades provide a standardized way to communicate viscosity specifications, ensuring compatibility with various machinery.

What is Viscosity Index (VI)?

The Viscosity Index (VI) is a numerical scale of how a lubricant’s viscosity changes with temperature variations. A high viscosity index is desirable as it indicates minimal viscosity change over a wide temperature range. This characteristic ensures consistent lubricant performance, particularly in environments with fluctuating temperatures.

High VI lubricants effectively maintain lubrication film integrity, preventing boundary lubrication conditions that can lead to increased friction and wear. This is especially critical in industrial settings where machinery operates under variable temperature conditions.

Benefits of a High Viscosity Index in Maintaining Consistent Performance

- Enhanced Lubricant Performance

One of the primary benefits of a high viscosity index is its ability to maintain consistent lubricant performance across a range of temperatures. Unlike lubricants with lower viscosity indices, which may experience significant viscosity changes with temperature fluctuations, high VI lubricants retain their viscosity characteristics, ensuring optimal lubrication efficiency and film thickness regardless of operating conditions. - Improved Wear Protection

High viscosity index lubricants provide enhanced wear protection by maintaining a stable lubricating film between moving parts, even in extreme temperature environments. This stable lubricating film helps prevent metal-to-metal contact and reduces friction, thus minimizing wear and extending the lifespan of critical machinery components. - Enhanced Fuel Efficiency

In automotive and transportation applications, high viscosity index lubricants contribute to improved fuel efficiency by reducing internal friction and mechanical losses within the engine. By maintaining consistent viscosity characteristics across a wide temperature range, these lubricants help optimize engine performance and reduce fuel consumption, leading to cost savings and environmental benefits. - Extended Oil Change Intervals

The stability of high viscosity index lubricants allows for extended oil change intervals, reducing maintenance frequency and downtime associated with lubricant replacement. With fewer oil changes required, businesses can realize cost savings and operational efficiencies while ensuring continuous machinery uptime. - Optimal Performance in Extreme Conditions

High viscosity index lubricants excel in extreme operating conditions, including high temperatures, cold starts, and heavy load conditions. Their ability to maintain consistent viscosity and lubricating properties under such conditions makes them ideal for use in critical machinery and equipment where reliability is paramount. - Environmental Benefits

By reducing the need for frequent oil changes and improving fuel efficiency, high viscosity index lubricants contribute to environmental sustainability by minimizing waste generation and reducing greenhouse gas emissions associated with lubricant usage. - Cost Savings and Operational Efficiency

The combined benefits of extended oil change intervals, improved fuel efficiency, and enhanced wear protection translate into significant cost savings and operational efficiency for businesses. By investing in high viscosity index lubricants, businesses can optimize machinery performance, minimize maintenance costs, and maximize profitability.

In conclusion, mastering lubrication science is essential for ensuring the efficiency and longevity of industrial machinery. Viscosity and viscosity index are key parameters that dictate lubricant performance across a range of operating conditions. With Fluid Solutions as your trusted partner, you can navigate the complexities of lubrication science with confidence through our lubrication consultants.

Choose Fluid Solutions for Industrial Lubricant Solutions

Fluid Solutions stands as the metalworking fluids manufacturer and premier provider of industrial lubrication solutions in the Philippines, offering a comprehensive range of products tailored to meet the diverse needs of our clients.

Whether it’s lubricant with different viscosity ranges, hydraulic oils, gear oils or specialized industrial lubricant solutions, Fluid Solutions delivers quality and reliability. Additionally, our team of Lubrication Consultants is dedicated to addressing concerns and inquiries promptly, ensuring a response within 24 hours to provide expert guidance and support.

Contact Fluid Solutions today at (02) 8370 5928 / (0917) 894 9156 or via email at inquiry@fluidsolutions.com.ph to learn more about how we can enhance the performance and longevity of your equipment.