The consistency of lubricating grease is crucial as it determines its suitability for specific applications, particularly its ability to resist leakage and form stable lubricant channels within bearings. These channels act as reservoirs for bearing functionality throughout the machine’s operational lifespan.

The consistency of grease depends on the type and amount of thickener used, as well as the viscosity of its base oil. It refers to the grease’s ability to resist deformation under force, measured by penetration, which can be influenced by handling or usage.

The National Lubricating Grease Institute classifies grease consistency. This blog explores how grease stiffness is measured and its applications across NLGI grades.

NLGI in a Nutshell

The National Lubricating Grease Institute is a non-profit organization founded in 1933, whose mission is to disseminate relevant information for grease manufacturing and usage. NLGI serves grease manufacturers and end-users, aiming to strengthen its association through continuous service delivery.

Today, NLGI comprises over 200 member companies across 31 countries, including grease manufacturers, additive suppliers, distributors, original equipment manufacturers, end users, and educators.

Membership is company-based and includes equipment, supplies, and services suppliers, along with research, educational groups, and technical-focused companies.

Measuring Grease Consistency

Grease consistency refers to the resistance of grease to deformation under force, distinct from viscosity.

The cone penetration test defined by ASTM D217 is the primary method to measure grease consistency. This test uses a cone dropped into a grease sample for 5 seconds, measuring the depth of penetration to determine consistency. ASTM D1403 provides scaled-down alternatives for smaller sample sizes.

Using a rheometer has become increasingly common for assessing grease rheological properties. This device requires a small sample size (<2 grams), offering precise quantitative results with temperature control, often surpassing the cone test in accuracy and simplicity. Rheological tests evaluate viscoelastic properties like critical stress.

Grease behaves as a viscoelastic solid, exhibiting solid properties until sheared past a critical point where it begins to flow. Defining this critical state varies, but oscillatory tests identify vital points, such as the yield and flow points, widely used in grease characterization.

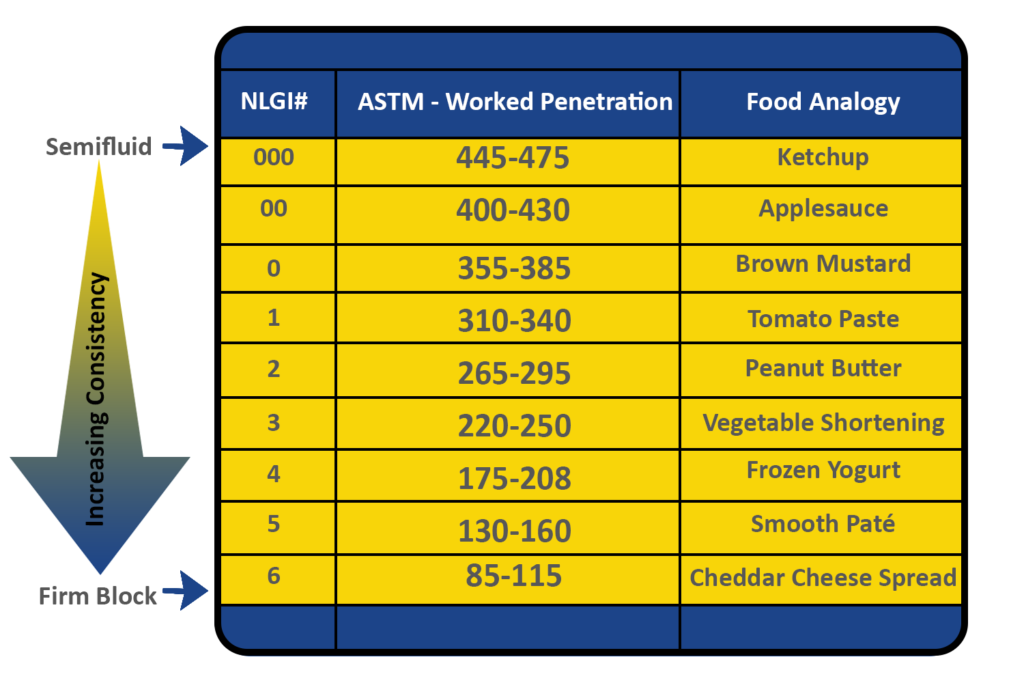

The NLGI scale ranges from 000 (semifluid) to 6 (block greases), indicating softer greases with higher penetration values. Thicker greases, with more thickener, offer greater resistance to water and high temperatures.

NLGI Classification of Grease Stiffness

Consistency in grease refers to its stiffness, which ensures it remains in bearings without excessive friction. Grease lubrication is suitable for open and enclosed gear systems operating at low speeds.

NLGI classifies grease on a scale where lower numbers indicate softer consistency. Bearings typically use NLGI grades 1, 2, or 3.

Softer greases with higher penetration values may migrate away from lubrication areas, while stiffer greases with lower values may struggle to penetrate these areas effectively.

Applications of Different NLGI Grades

Softer Semi-Flowing Greases (NLGI 000 and 00)

NLGI Grades 000-0 greases are fluid to semifluid, less viscous options suitable for enclosed and centralized applications. It is used for open gear systems where greases are sprayed or used as a bath.

NLGI 000: Liquid-like grease with minimal thickener, suitable for sliding surfaces, guides, and centralized lubrication systems with low-temperature pumpability.

NLGI 00: Like NLGI 000, used for open gears, spur gears, and bearings in both standard and severe conditions.

NLGI 0: Semifluid grease with good flow and low temperature pumpability, ideal for roller bearings, chains, and enclosed gearboxes.

NLGI 1: Soft, tomato-paste-like consistency, suitable for bearings and electric drive applications.

NLGI 2: Peanut-butter-like consistency, widely used in automotive and industrial applications, including bearings and flexible couplings. Some grease suppliers use descriptions like NLGI Number 1.5, indicating a consistency between NLGI Numbers 1 and 2.

Stiffer Greases (NLGI 3 or higher)

NLGI 3: Semi-solid grease for automotive, industrial, and marine applications, offering good sealing properties.

NLGI 4: Moderately stiff grease for water pumps and high-speed, lightly loaded applications.

NLGI 5: Stiff grease with low oil separation, used in overhead conductors and high-speed applications.

NLGI 6: Very stiff grease, uncommon, used in pillow-block lubrication and high-speed applications requiring minimal oil separation.

Fluid Solutions: Your Trusted Grease Supplier in the Philippines

Fluid Solutions is a leading manufacturer of metalworking fluids and industrial lubrication solutions. We offer a wide range of greases—from multipurpose greases to extreme pressure greases—with various NLGI grades.

We empower businesses to protect machinery and optimize performance with our expertise and commitment to quality.

The Fluid Solutions team provides lubrication solutions that boost productivity and extend component life. Our commitment includes delivering goods and services promptly, conducting business with honesty and transparency, responding to client communications within 24 hours, and offering excellent pre- and post-sale services.

Looking for a trusted and reliable grease supplier in the Philippines? Contact us at (02) 8370 5928 / (0917) 894 9156 or drop by our inbox at inquiry@fluidsolutions.com.ph for personalized guidance on selecting the right lubricants for your needs. You can also visit our Facebook or LinkedIn page to learn more about our products and services.