Mineral-based lubricants serve as the backbone of many industrial operations, providing essential functions to keep machinery running smoothly. These lubricants, derived from crude oil, offer a cost-effective solution for a range of applications. Selecting the right lubricant can significantly impact the performance and longevity of the machinery. This article offers a straightforward exploration, defining mineral oils, examining the composition of lubricants, understanding the extraction of base oils from crude oil, and exploring base oil classifications. As the leading provider of industrial lubrication solutions in the Philippines, Fluid Solutions emphasizes the importance of understanding different lubricant base oil types for optimal selection.

What are Mineral-based Lubricants?

Definition of Mineral-Based Lubricants

Mineral-based lubricants, also known as conventional or petroleum-based lubricants, are derived from crude oil through a refining process. These lubricants are the backbone of many industrial and automotive applications due to their affordability and availability. They provide essential functions such as reducing friction, minimizing wear and tear, and dissipating heat, thereby ensuring machinery operates smoothly.

Significance in Industrial and Automotive Applications

Mineral-based lubricants are widely used in various industries, from manufacturing and transportation to agriculture and construction. Their versatility makes them suitable for a range of applications, including engines, hydraulic systems, gearboxes, and more. Their ability to perform under diverse conditions makes them an indispensable part of industrial operations.

Lubricant Composition: Base Oil and Additives

Components of Lubricants

Lubricants consist of two primary components: base oil and additives. The base oil serves as the primary lubricating fluid, while additives enhance specific properties such as viscosity, anti-wear capabilities, and resistance to oxidation. The combination of these elements ensures optimal performance in diverse operating conditions.

Role of Additives

Additives play a crucial role in enhancing the performance of lubricants. They improve viscosity, protect against wear and tear, prevent oxidation, and enhance the lubricant’s ability to function under extreme temperatures. A well-balanced combination of base oil and additives is essential for ensuring the lubricant meets the specific requirements of different machinery and applications.

Extraction From Crude Oil

Refining Process

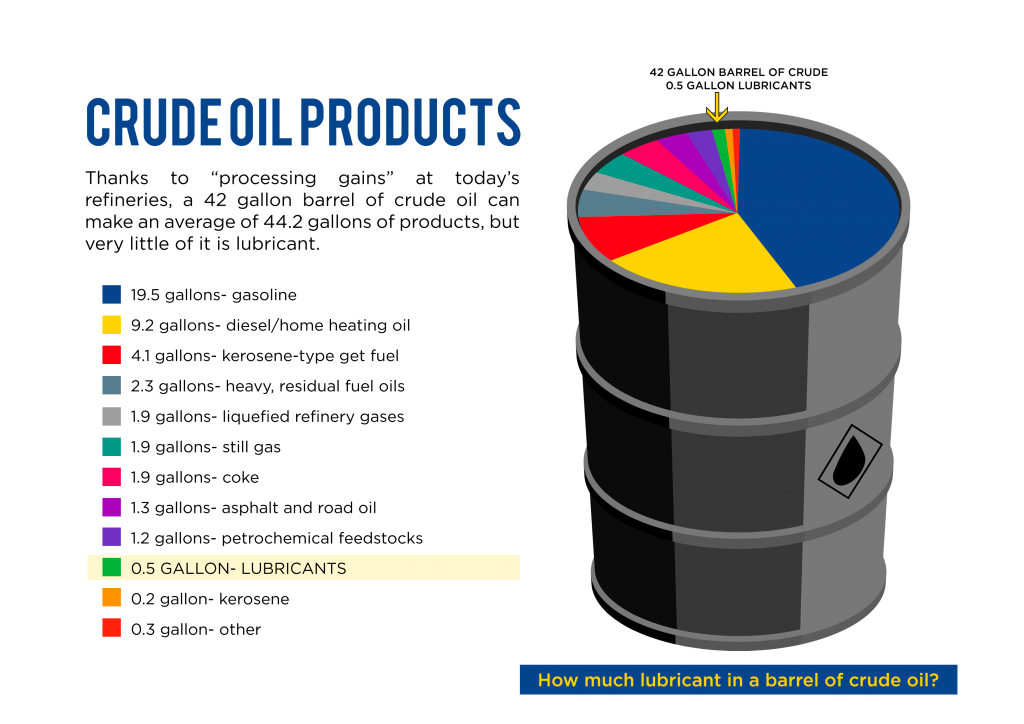

The base oil in mineral lubricants is extracted from crude oil through a refining process. Crude oil, a complex mixture of hydrocarbons, undergoes distillation and other refining steps to isolate the desired fractions. The resulting base oil is then blended with additives to create lubricants tailored for different applications. The refining process involves several stages, including distillation, hydrocracking, and solvent extraction, to produce high-quality base oils.

Importance of Refining

Refining is critical in isolating the desired fractions for lubricant formulation. The quality of the base oil directly impacts the performance of the final lubricant. Proper refining ensures that impurities are removed, and the base oil has the necessary properties to meet the demands of various applications.

Base Oil Classifications

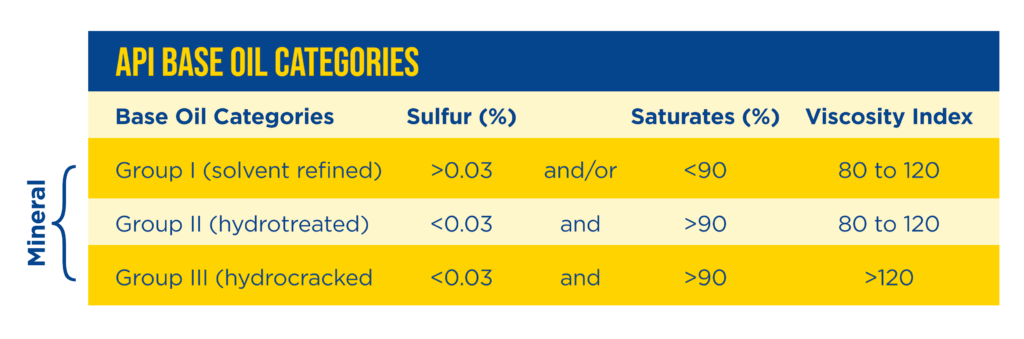

Base oils can be categorized into different groups based on their refining processes, such as Group I, II, or III. The selection of types of base oils influences the lubricant’s viscosity, temperature stability, and overall performance characteristics.

Comparison of Base Oil Groups

Group I base oils are cost-effective and suitable for less demanding applications, while Group II and III base oils for lubricants offer enhanced performance for more critical applications. Understanding the differences between these groups helps in selecting the right lubricant for specific needs.

a. Paraffinic Base Oils

- Properties

Paraffinic base oils are derived from the refining of paraffinic crude oil. They offer excellent oxidation stability and low-temperature properties, making them suitable for applications where stability and low-temperature fluidity are critical.

- Common Applications

Paraffinic base oils are commonly used in automotive engine oils, hydraulic fluids, and other applications where high stability and performance are required under varying temperature conditions.

b. Naphthenic Base Oils

- Characteristics

Naphthenic base oils are extracted from naphthenic crude oil. They provide better solubility with additives and improved thermal stability. These characteristics make them ideal for applications requiring enhanced solubility and heat dissipation.

- Industrial Applications

Naphthenic base oils are often chosen for transformer oils, industrial lubricants, and metalworking fluids, where their superior solubility and thermal properties are beneficial.

c. Aromatic Base Oils

- Advantages

Aromatic base oils are derived from aromatic crude oil. They offer a superior viscosity index and excellent load-carrying capabilities. These properties make them well-suited for high-temperature applications and environments where heavy loads are common.

- Typical Uses

Aromatic base oils are commonly used in industrial gear lubrication, compressor oils, and other high-stress applications where robust performance is required.

Consulting with Lubrication Consultants

Importance of Expert Guidance

For businesses relying on machinery, seeking guidance from lubrication consultants is a prudent investment. These professionals can assess specific operational conditions, recommend suitable mineral-based lubricants based on base oil classifications, and provide tailored maintenance strategies. Their expertise ensures that businesses make informed decisions, optimizing machinery performance and minimizing downtime.

Role of Consultants

Lubrication consultants play a crucial role in assessing operational conditions and recommending suitable lubricants. They help in selecting the right base oil type, ensuring the lubricant meets the specific requirements of the machinery and operating environment.

Benefits of Expert Advice

Expert advice helps businesses optimize machinery performance, reduce maintenance costs, and minimize downtime. Consulting with lubrication experts ensures that the right lubricants are used, leading to improved efficiency and longevity of equipment.

Partner with Fluid Solutions

Fluid Solutions is the premier provider of base oils and lubrication solutions in the Philippines. We offer expert guidance on selecting the right lubricants for your machinery, ensuring optimal performance and longevity.

Contact Fluid Solutions today at (02) 8370 5928 / (0917) 894 9156 or via email at inquiry@fluidsolutions.com.ph for hydraulic fluid prices and tailored lubrication solutions that meet your specific needs.