Blog Topics

All Blogs

Understanding the Components of Straight-Cutting Oils

Learn about what makes up straight-cutting oils. Discover how these components work together to enhance metalworking processes.

How Rust Preventive Oils Work: Functions and Applications

Learn how rust preventive oils work and their applications in protecting metal surfaces from corrosion.

The Different Types of Rust Preventives: A Comprehensive Guide

Learn about the types of rust preventives, their protection durations, and base types. Find the best rust inhibitor for your needs.

Step-by-Step Guide to Regreasing Electrical Motors for Optimal Performance

Learn how to properly regrease electrical motors for optimal performance. Follow these steps to prevent overheating and extend the motor's lifespan.

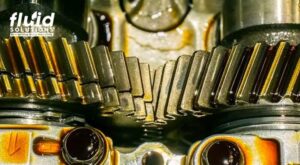

How Cutting Oils Improve High-Friction Machining

Learn when to use cutting oils for high-friction machining operations. Discover how these oils optimize tool life and part quality in slow-speed applications.

Stop Rust in Machining: Effective Coolant and Fluid Management Tips

Avoid costly rust damage in machines by maintaining proper coolant concentration and pH levels. Follow these best practices to ensure rust-free metal parts.

Preventing Bacterial Growth in CNC Coolants: Best Practices for Operators

Discover practical steps to stop bacterial contamination in CNC coolants, avoid foul odors, and maintain machine performance with these expert tips.

Mixing Cutting Coolants Correctly: Why It Matters for CNC Machines

Improper coolant mixing leads to poor machining results and shorter tool life. Learn how to mix coolants correctly to maintain consistent performance.

How to Properly Clean Your CNC Machine Sump for Optimal Coolant Performance

Learn how to properly clean your CNC machine sump to extend coolant life. Follow these sumps cleaning best practices for optimal results.