Lubricants play a pivotal role in ensuring smooth and efficient operations. The performance of these lubricants is heavily influenced by their viscosity, a measure of a fluid’s resistance to flow. For lubricants, viscosity is a crucial property that determines their effectiveness under different operating conditions. One of the critical factors affecting viscosity, especially in low-temperature environments, is the Pour Point.

What is Pour Point?

Definition of Pour Point

All lubricants and Newtonian fluids exhibit an increase in viscosity as temperatures decrease. At a certain (very low) temperature, a lubricant may solidify also and cease to flow, and thus fail to lubricate.

Pour Point is defined as the lowest temperature at which a fluid, such as a lubricant, remains pourable. In other words, it is the temperature at which a lubricant becomes too viscous to flow or ceases to flow altogether. The pour point provides a benchmark for assessing the cold-temperature performance of lubricants, helping to ensure they remain effective in sub-zero environments and applications such as cold storage and food & beverage industries.

The Pour Point is therefore measured typically with lubricants, wherein Pour Point is the lowest (coldest) temperature that a fluid will still flow, though at a low flow ability rate. Normally, Pour Points of mineral based-lubricants are below zero (0) degrees Centigrade (example -10°C); synthetic lubricants, on the other hand, can provide pour points as low as -30°C to -40°C.

How Pour Point is Measured

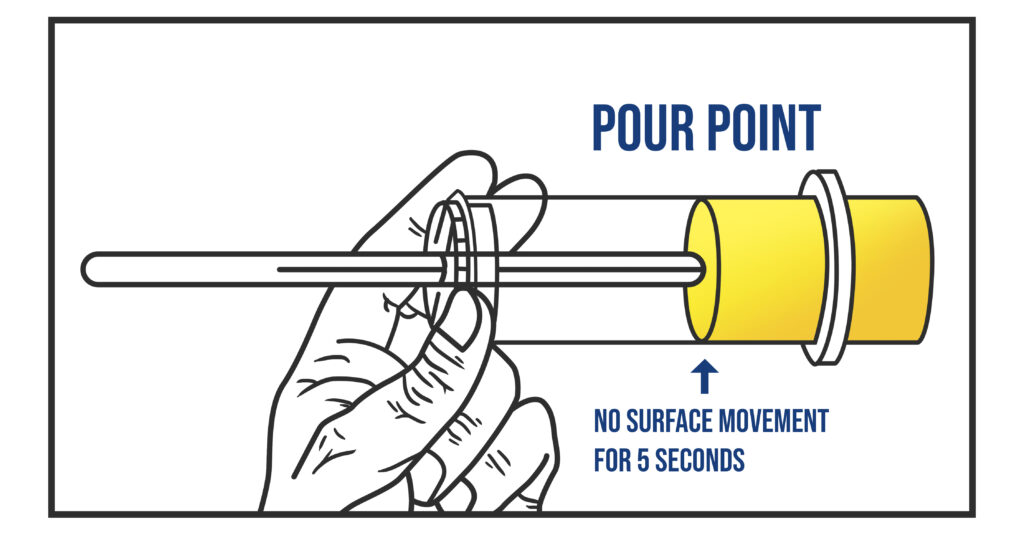

The measurement of the Pour Point is standardized to ensure consistency and reliability. Typically, the process involves cooling the lubricant sample in a controlled environment and periodically tilting the container to check if the fluid still flows. The lowest temperature at which movement is observed is recorded as the Pour Point. This test is crucial for understanding how a lubricant will perform in real-world low-temperature applications.

The Importance of Pour Point in Lubricants

Impact of Low Temperatures on Lubricant Viscosity

As temperature drops, the viscosity of lubricant increases. This means the lubricant becomes thicker and flows more slowly. In extremely cold conditions, the lubricant may reach its Pour Point, becoming so viscous that it ceases to flow altogether. This can lead to inadequate lubrication, increased friction, and potential damage to machinery.

Consequences of a Lubricant Reaching its Pour Point

When a lubricant reaches its Pour Point and stops flowing, it can no longer provide the necessary lubrication to protect the moving parts. This can result to increased wear and tear, higher energy consumption, and even catastrophic equipment failures. Understanding and selecting lubricants with appropriate Pour Points is essential in maintaining machinery reliability, particularly in cold climates and applications.

● Increased Wear and Tear

Lubricants are crucial for reducing friction between moving parts. When a lubricant reaches its Pour Point, it solidifies and can no longer provide a protective film. This lack of lubrication leads to metal-on-metal contact, causing parts to wear out more quickly. Over time, this increased wear and tear can significantly shorten the lifespan of machinery components, leading to more frequent repairs and replacements.

● Higher Energy Consumption

Machinery operates more efficiently when its parts are properly lubricated. When lubricants solidify, the increased friction between parts causes the machinery to work harder to perform the same tasks. This additional effort requires more energy, leading to higher operational costs. In environments where energy efficiency is critical, such as in cold storage facilities, this can be a significant drawback.

● Catastrophic Equipment Failures

The most severe consequence of a lubricant reaching its Pour Point is the potential for catastrophic equipment failures. Without proper lubrication, moving parts can seize up or break, causing sudden and often extensive damage. This not only leads to costly repairs but can also result in operational downtime, affecting productivity and potentially leading to missed deadlines or compromised safety.

Comparison of Mineral-Based and Synthetic Lubricants

Typical Pour Points of Mineral-Based Lubricants

Mineral lubricants are derived from crude oil and are commonly used due to their cost-effectiveness and availability. However, they generally have higher Pour Points compared to synthetic lubricants. For instance, the Pour Points of mineral-based lubricants typically range around -10°C. This higher Pour Point can limit their effectiveness in extremely cold environments.

Advantages of Synthetic Lubricants in Terms of Lower Pour Points

Synthetic lubricants are engineered to perform better under a wide range of temperatures. They can have Pour Points as low as -30°C to -40°C, making them more suitable for extreme cold conditions. The lower Pour Points of synthetic lubricants ensure they remain fluid and effective even in harsh winter climates, providing better protection for machinery and extending equipment life. Additionally, synthetic lubricants, including grease lubricant varieties, are designed to maintain their consistency and performance across a broader temperature range, further enhancing machinery reliability.

Conclusion

Understanding the concept of Pour Point is essential in selecting the right lubricants for specific applications, especially in low-temperature environments. The choice between mineral-based and synthetic lubricants can significantly impact machinery performance, with synthetic lubricants offering advantages due to their lower Pour Points. By carefully considering the Pour Point, industries can ensure reliable and efficient operations even under extreme frigid conditions.

Optimize Your Lubricant Performance with Fluid Solutions

Partnering with Fluid Solutions can help you optimize your lubricant performance. We offer expert advice and a range of high-quality lubricants designed to excel in low-temperature environments.

Contact Fluid Solutions today at (02) 8370 5928 / 0917) 894 9156 or via email at inquiry@fluidsolutions.com.ph to learn more about our products and how we can help you maintain efficient and reliable operations, regardless of the temperature.