Single point automatic lubricators are instrumental in modern machinery maintenance, providing a simplified and effective approach to lubrication. This article explores the definition of single point automatic lubricators, outlines common parts and specifications, delves into their advantages and limitations, and underscores the importance of consulting with lubrication consultants for optimal usage.

Single Point Lubricators

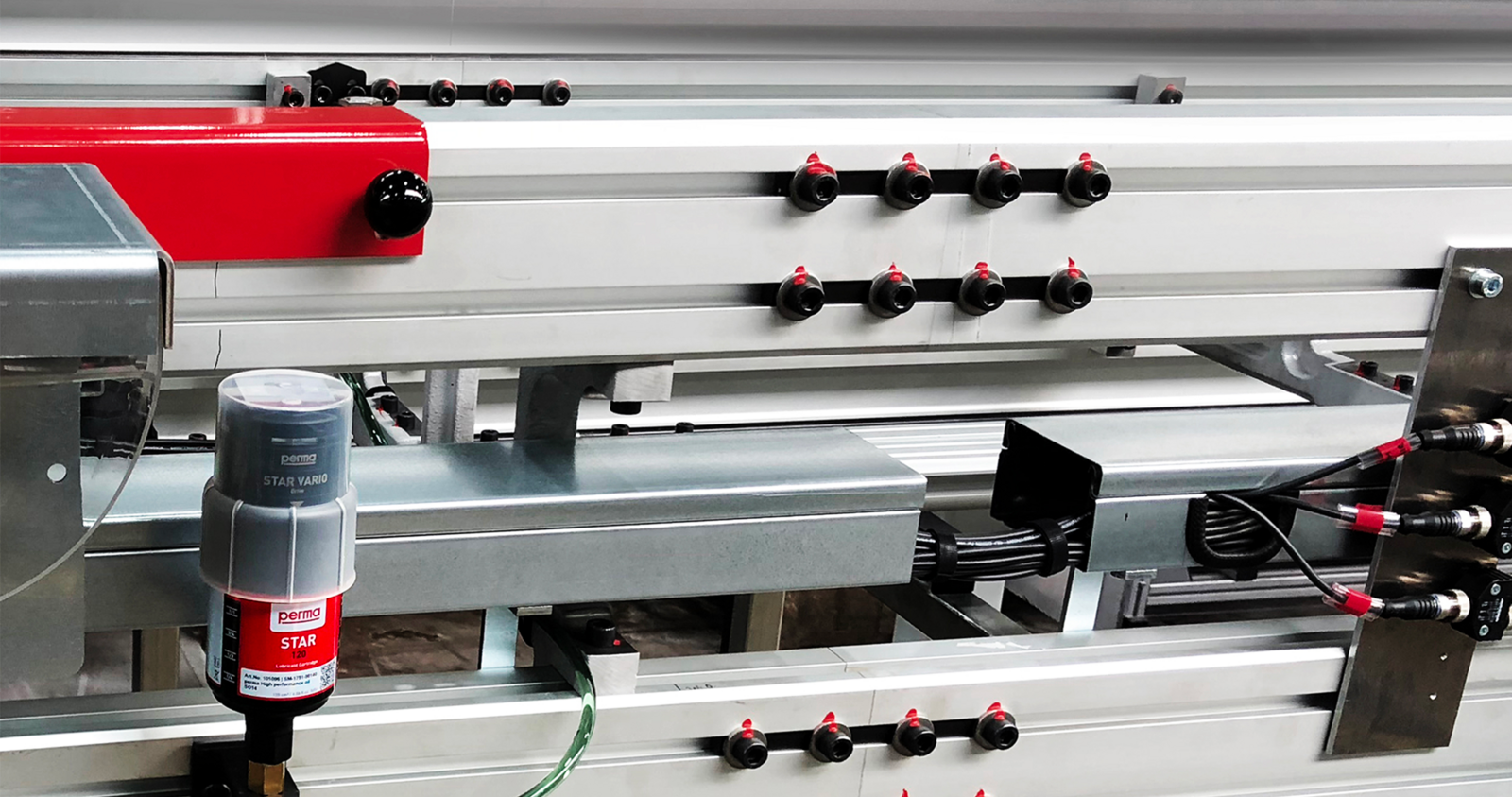

Single point automatic lubricators, or single-pointers, are compact devices designed to automatically dispense a controlled amount of lubricant to a specific lubrication point within machinery. These units operate independently, ensuring a continuous and precise supply of lubrication, reducing the need for manual intervention.

Common Parts and Specifications

Reservoir

The reservoir stores the lubricant and comes in various sizes to accommodate different application requirements. It ensures a steady and controlled supply of lubricant over time.

Dispensing Mechanism

The dispensing mechanism regulates the flow of lubricant, allowing for precise delivery to the lubrication point. It can be adjusted to meet the specific lubrication needs of the machinery.

Power Source

Single point automatic lubricators typically utilize batteries or gas pressure to power the dispensing mechanism. This autonomy reduces the need for frequent attention and maintenance.

Mounting Options

These lubricators offer flexible mounting options, allowing for easy installation in various positions and locations within machinery. This adaptability enhances their usability in diverse industrial settings.

Benefits of Using Single Point Lubricators

Continuous Lubrication

Single point automatic lubricators ensure a continuous and consistent supply of lubricant to critical machinery components. This prevents wear and tear, extends the lifespan of equipment, and enhances overall operational efficiency.

Reduced Manual Intervention

By automating the lubrication process, these systems minimize the need for manual intervention. This not only saves time and labor costs but also reduces the likelihood of human error in lubrication application.

Precise Lubricant Delivery

The dispensing mechanism allows for precise control over the amount of lubricant delivered to the lubrication point. This precision ensures optimal lubrication without wastage.

Limitations of Single Point Lubricators

Limited Capacity

Single point automatic lubricators typically have limited reservoir capacities. In applications with high lubricant consumption, frequent replenishment may be necessary.

Applicability to Specific Points

While effective for targeted lubrication points, these lubricators may not be suitable for applications requiring lubrication across a broad area.

Consult with Lubrication Consultants

For businesses aiming to implement single point automatic lubricators effectively, consulting with lubrication consultants is highly recommended. Lubrication experts can assess specific operational conditions, recommend the most suitable lubrication solutions, and provide guidance on proper installation and maintenance practices. Their expertise ensures businesses make informed decisions, optimizing machinery performance and minimizing downtime.