Synthetic oils have become essential components in various industries, providing unparalleled performance and protection for machinery. This article offers a straightforward overview, defining synthetic oils, exploring common types, highlighting the advantages of synthetic oils over mineral oils, discussing semi-synthetic lubricants, and emphasizing the importance of consulting with lubrication experts.

Synthetic Oils

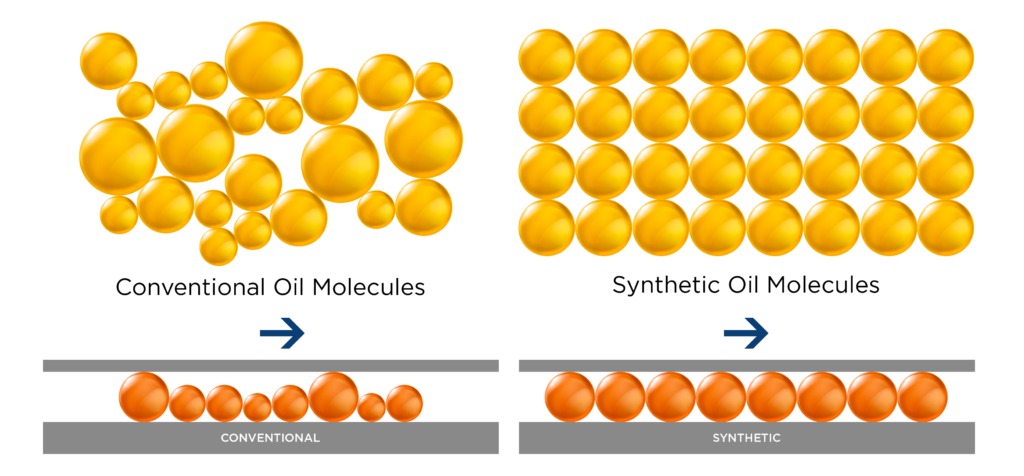

Synthetic oils are precisely engineered lubricants formulated in laboratories to meet specific performance criteria. Unlike mineral oils derived from crude oil, synthetics are crafted from carefully selected base oils and additives. They are produced chemically, with the aim of performing in a much better manner than Group I, Group II and Group III mineral-based Base Oils. The molecular structures of Synthetic Base Oils are tailor-made to be smaller, uniform and more stable (vs. mineral-based oils). There are also lesser contaminants as compared to conventional base oils, ensuring optimal performance across diverse applications.

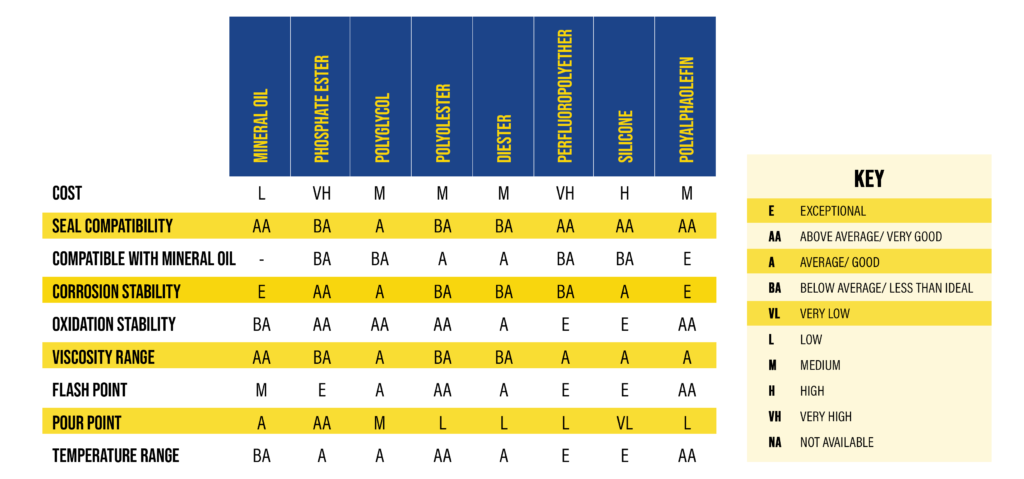

Common Types of Synthetic Oils

Polyalphaolefin (PAO)

PAO synthetic oils are known for their excellent thermal stability and resistance to oxidation. They perform well across a broad temperature range, making them suitable for both high and low-temperature applications.

Ester-based Oils

Ester-based synthetic oils are celebrated for their superior lubricity and biodegradability. Often chosen for applications requiring extreme pressure and temperature resistance, these oils provide exceptional performance.

Polyalkylene Glycol (PAG)

PAG synthetic oils are valued for their ability to offer outstanding anti-wear and extreme pressure properties. They find common usage in industrial gearboxes and hydraulic systems.

Advantages of Synthetic Oils vs Mineral Oils

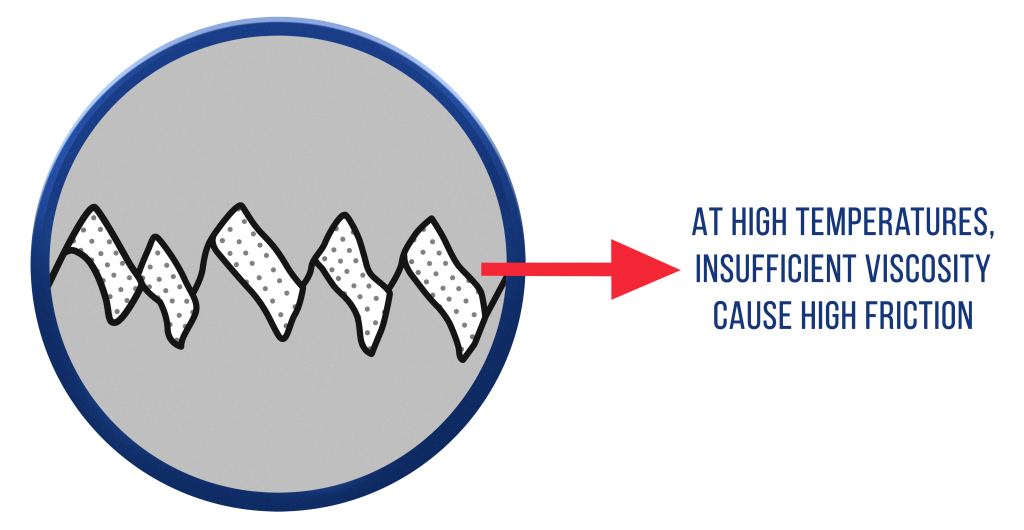

Temperature Stability

Synthetic oils exhibit superior thermal stability, resisting breakdown at high temperatures. This characteristic ensures consistent lubrication performance, even in demanding operating conditions.

Oxidation Resistance

Synthetic oils are less prone to oxidation compared to mineral oils. This resistance minimizes the formation of sludge and deposits, promoting cleaner and more efficient machinery operation.

Wear Protection

The molecular precision in synthetic oils provides enhanced wear protection, reducing friction and extending the lifespan of machinery components. This is particularly advantageous in high-stress environments.

Cold-Weather Performance

Synthetic oils maintain their fluidity in cold temperatures, unlike mineral oils that can thicken. This property ensures effective lubrication even in sub-zero conditions, a critical factor for machinery operating in diverse climates.

Semi-Synthetic Lubricants

Semi-synthetic lubricants, also known as blends, combine synthetic and mineral oil components. This hybrid approach aims to harness the benefits of both types while managing costs effectively. Semi-synthetics offer improved performance over pure mineral oils, providing a cost-effective solution for various applications.

Consult with Lubrication Consultants

For businesses seeking to optimize machinery performance, consulting with lubrication experts is invaluable. These professionals can assess specific operational requirements, recommend the most suitable synthetic oils or blends, and provide guidance on maintenance practices. Their expertise ensures that businesses make informed decisions, optimizing machinery performance and minimizing downtime.

Synthetic Lubricants Explained

Synthetic lubricants are precisely engineered solutions created in laboratories. Unlike conventional mineral-based lubricants, synthetics are designed for specific performance and durability standards. Synthetic base oils form the core of these lubricants, contributing to their exceptional qualities.

Applications of Synthetic Lubricants

The versatility of synthetic lubricants spans a multitude of industries and applications. From automotive engines and aerospace systems to industrial machinery and beyond, synthetic lubricants are favored where optimal performance, extended service intervals, and resistance to extreme conditions are paramount. Their ability to excel in high-temperature environments and demanding operational settings makes them indispensable in critical machinery.

Advantages of Synthetic Base Oils

At the core of synthetic lubricants are advanced base oils, notably Poly-Alpha Olefins (PAO) and Esters. These synthetic base oils confer several advantages:

Thermal Stability: PAO and Esters exhibit remarkable thermal stability, ensuring lubricants maintain their integrity and performance under high-temperature conditions.

Extended Lifespan: Synthetic base oils resist oxidation, contributing to a longer lubricant life. This not only enhances equipment longevity but also reduces maintenance requirements.

Low-Temperature Performance: Synthetic lubricants, thanks to their carefully engineered base oils, perform exceptionally well in low temperatures, ensuring reliable lubrication even in cold environments.

Difference between Mineral Oils and Synthetic Base Oils

The contrast between mineral oils and synthetic base oils lies in their origin and composition. Mineral oils are extracted from crude oil, whereas synthetic base oils are intricately synthesized. This synthetic process allows for precise engineering, resulting in consistent and exceptional performance characteristics. Synthetic base oils resist temperature extremes, oxidation, and exhibit enhanced stability, setting them apart from their mineral oil counterparts.

It’s essential to exercise caution with products labeled as “semi-synthetic” or “synthetic-blends.” While they may contain some synthetic components, their performance may not match that of full synthetic lubricants. Industries should carefully assess their specific lubrication needs and consult with experts to ensure optimal performance and longevity for their equipment.

Synthetic lubricants, driven by advanced base oils, represent the pinnacle of lubrication precision. Their applications span critical industries, offering efficiency and reliability where it matters most. The advantages of synthetic base oils underscore the transformative impact of synthetic lubricants in the ever-evolving landscape of machinery lubrication. Understanding these nuances, including cautious consideration of product labels, empowers industries to ensure optimal performance and longevity for their valuable equipment.