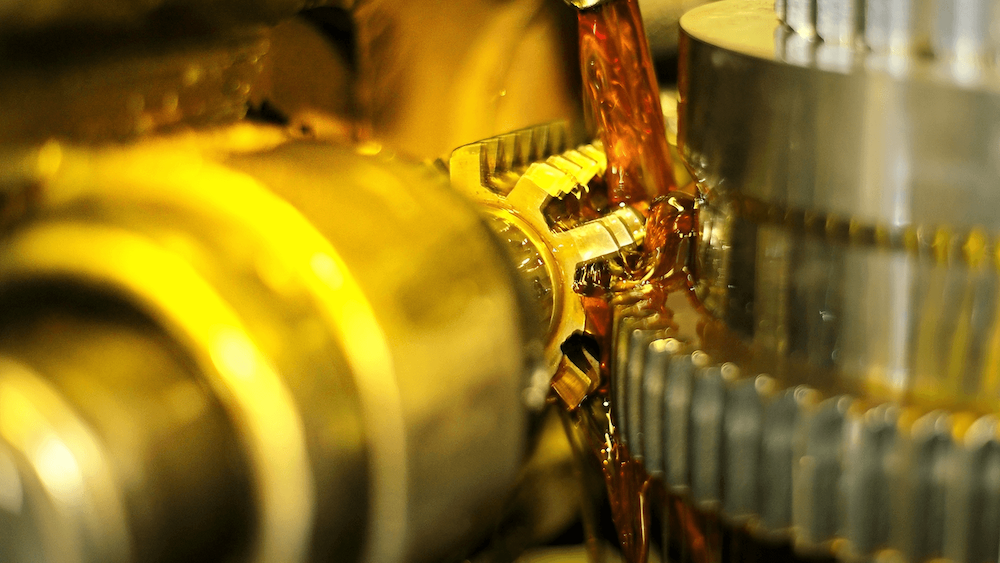

Industrial lubricants play a crucial role in ensuring the smooth operation and longevity of machinery across various sectors. Understanding their uses involves delving into their primary functions, which are geared toward reducing friction and wear, as well as their secondary functions that contribute to overall system efficiency.

Industrial lubricants are specialized substances used to reduce friction between moving surfaces within machinery. They come in various forms, including oils and greases, tailored to meet the specific requirements of diverse industrial applications.

Primary Functions of Lubricants

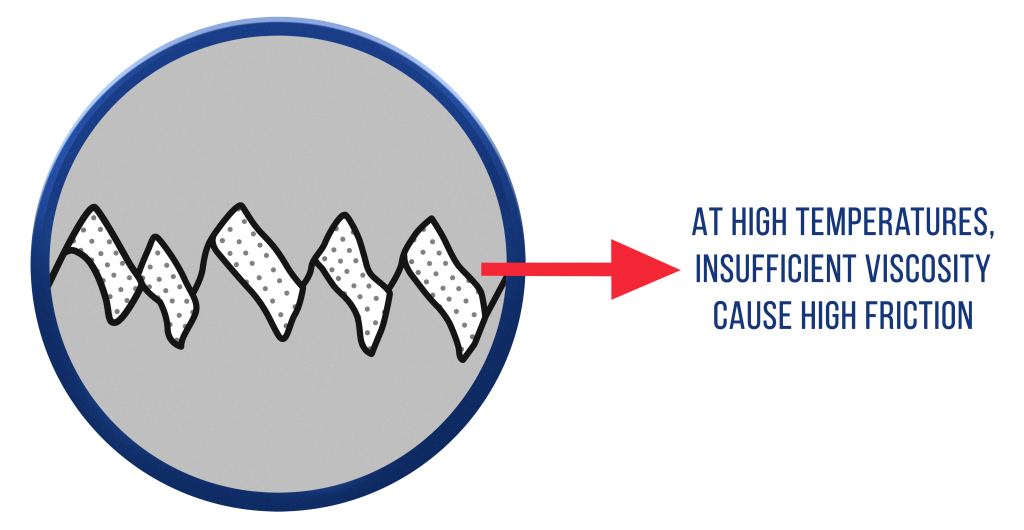

Friction Reduction

The core function of industrial lubricants is to minimize friction between moving parts. By forming a protective layer between surfaces, lubricants enable smoother motion, reducing heat generation and wear.

Wear Prevention

Lubricants act as a barrier, preventing direct contact between metal surfaces. This significantly reduces wear and tear on machinery components, leading to prolonged equipment life.

Secondary Functions of Lubricants

Beyond their primary role in friction reduction, industrial lubricants boast a multitude of secondary functions that contribute to the robust health of machinery.

Rust and Corrosion Protection

Industrial environments often expose machinery to harsh conditions, including moisture and corrosive agents. Lubricants act as protective shields, forming a barrier that safeguards against rust and corrosion. This preservation of machinery integrity is crucial for preventing degradation and maintaining optimal functionality.

Medium for Generating Force

In many industrial applications, lubricants serve as a medium for generating force such as in hydraulic systems. They facilitate the smooth transfer of power between mechanical components, ensuring that machinery operates seamlessly and efficiently. This function is particularly vital in heavy machinery and intricate systems where force transmission is a critical component of operation.

Heat Absorption

The efficient absorption of heat during machinery operation is another essential function of industrial lubricants. As machines generate heat during their operation, lubricants act as heat sinks, preventing overheating and potential damage. This crucial role in thermal management contributes to the overall reliability of machinery.

Ensuring Cleanliness of Lubrication System

Industrial lubricants also play a pivotal role in maintaining the cleanliness of the lubrication system. By acting as a carrier for contaminants and debris, lubricants prevent the accumulation of particles that could compromise the efficiency and functionality of machinery. This function is vital for preventing premature wear and ensuring the long-term reliability of industrial equipment.

Consult with Lubrication Experts

In conclusion, the uses of industrial lubricants extend far beyond friction reduction. From protecting against wear and heat to preventing corrosion and acting as effective sealants, these substances are essential for the seamless functioning and longevity of machinery in diverse industrial settings. To unlock the full potential of industrial lubricants, consult with lubrication experts who can provide personalized advice to meet the unique requirements of your machinery.