Plastic Forming

In the plastic forming industry, addressing stringent lubrication requirements is a fundamental challenge. Machinery involved in processes such as injection molding and extrusion operates under high pressures and temperatures, requiring lubricants that can endure these extreme conditions. The challenge is to find lubrication solutions that not only optimize performance but also ensure the seamless operation of plastic forming equipment.

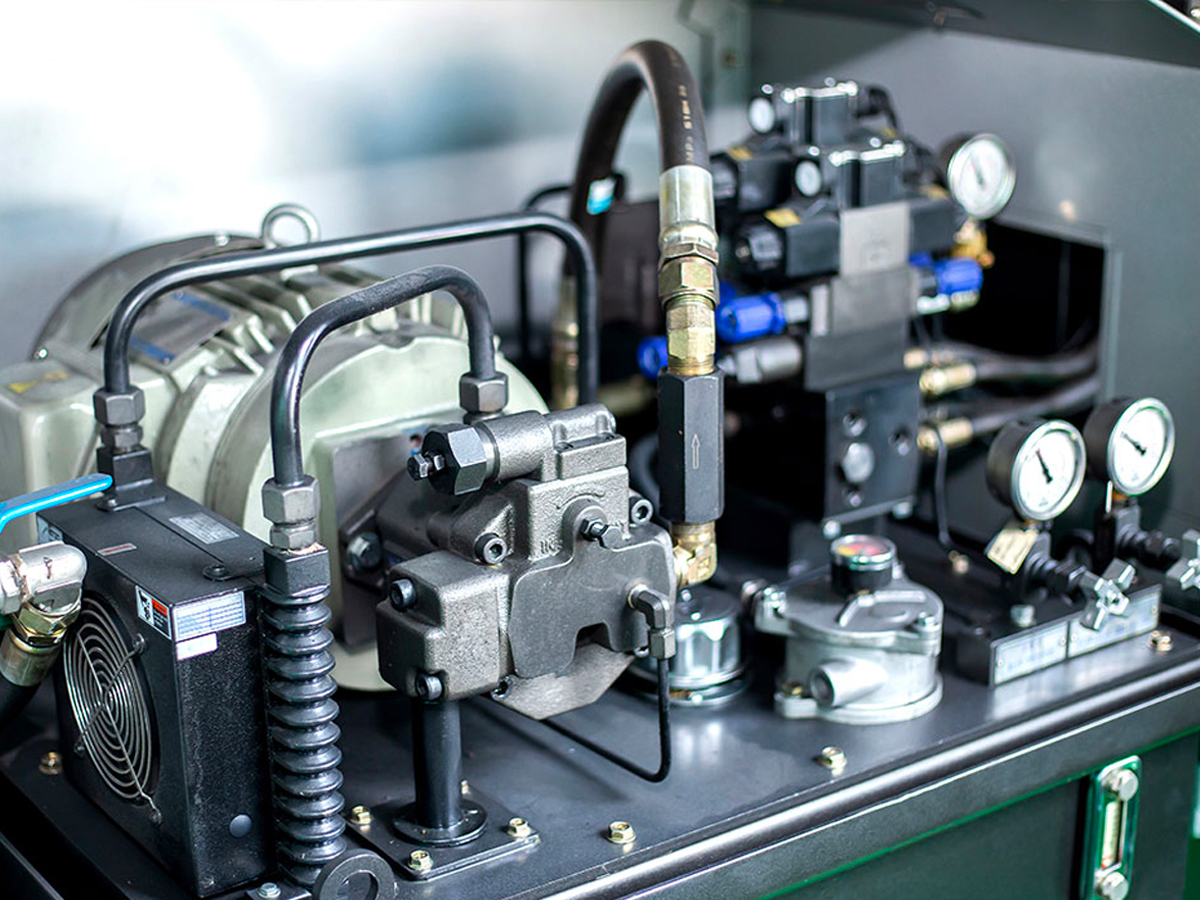

Various machines and processes within plastic forming demand specific types of lubricants. From the intricate movements of molds in injection molding machines to the continuous operation of extrusion equipment, lubricants play a pivotal role in minimizing friction and wear. Fluid Solutions emerges as a reliable partner, offering a comprehensive range of lubrication products meticulously formulated to meet the unique demands of the plastic forming industry. Our products contribute to the efficiency and longevity of machinery, ensuring reliable performance in the production of plastic components.

Whether it's optimizing the performance of molds or ensuring the smooth operation of extrusion processes, our products deliver superior performance. Partner with Fluid Solutions for advanced lubrication solutions that support the efficiency and longevity of machinery in the plastic forming sector.