Masonry with Filter and Categories

- All

- Basic Lubrication

The Dangers of Low-Quality Greases

Avoid costly maintenance issues caused by poor lubrication. Learn how to identify high-quality greases for industrial applications.

Understanding the Relationship of Lubricants and Temperature

Discover how temperature impacts lubricant viscosity and oxidation, affecting machinery performance. Learn strategies for optimal lubricant management.

Step-by-Step Guide to Regreasing Electrical Motors for Optimal Performance

Learn how to properly regrease electrical motors for optimal performance. Follow these steps to prevent overheating and extend the motor's lifespan.

Mastering Machinery: How to Choose the Right Lubricant for Every Application

Learn how to choose the right lubricant for every application with our guide. Discover tips on selecting the best lubricants to enhance equipment performance.

Solid Contamination Levels in Lubricating Oils: Importance, Standards, and Best Practices

Ensure machinery longevity by maintaining low solid contamination levels in lubricating oils. Learn about NAS and ISO 4406 standards.

Preventing Contamination: Proper Storage Solutions for Lubricants and Greases

Learn how to store lubricants and greases properly to prevent contamination and ensure optimal performance. Follow these best practices.

The Effect of Water Contamination in Lubricant Degradation

Prevent costly equipment damage by understanding water contamination in lubricant degradation. Read on.

4 Ball Scar Test: What It Is and Why It Matters for Your Machinery

Ensure machinery performance with the 4 Ball Scar Test. Discover how this evaluates the wear-reduction of lubricants.

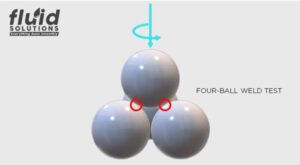

Lubricants Quality Check: Understanding the 4 Ball Weld Test

Learn about the importance of the 4 Ball Weld Test in evaluating the load-carrying capability of lubricants. Read on!

Table of Contents

Add a header to begin generating the table of contents