Grease is a semi-fluid to solid substance created by combining a liquid lubricant with a thickening agent. Unlike the more fluid oil, this blend results in a product that stays in place, providing consistent lubrication to machinery parts.

Greases are widely used across industries, ideal for machines operating irregularly or where frequent oil changes are impractical. Think of grease lubricant as a sponge holding lubricating oils and additives, releasing them to reduce friction when needed.

Grease exhibits several key properties that directly impact its effectiveness in diverse operational conditions. Read on to know more about the crucial properties of grease lubricants and their significance in selecting suitable grease for specific applications.

Grease Composition

Base Oil (80%–95%): The primary lubricating element, usually mineral oil, is suitable for various applications. Synthetic base oils are preferred in extreme temperatures for their enhanced stability.

Thickeners (5%-20%): Thickeners provide grease with a distinctive consistency. Common thickeners are metallic soaps like lithium and calcium or complex agents like polyurea. They hold the base oil and additives together, determining the grease’s performance and suitability for specific applications.

Additives (0%-10%): Additives enhance the grease’s properties, including oxidation and rust inhibitors, extreme pressure agents, anti-wear, and friction-reducing compounds, enabling the grease to withstand demanding conditions.

Lubrication Properties of Grease

Base Oil Viscosity

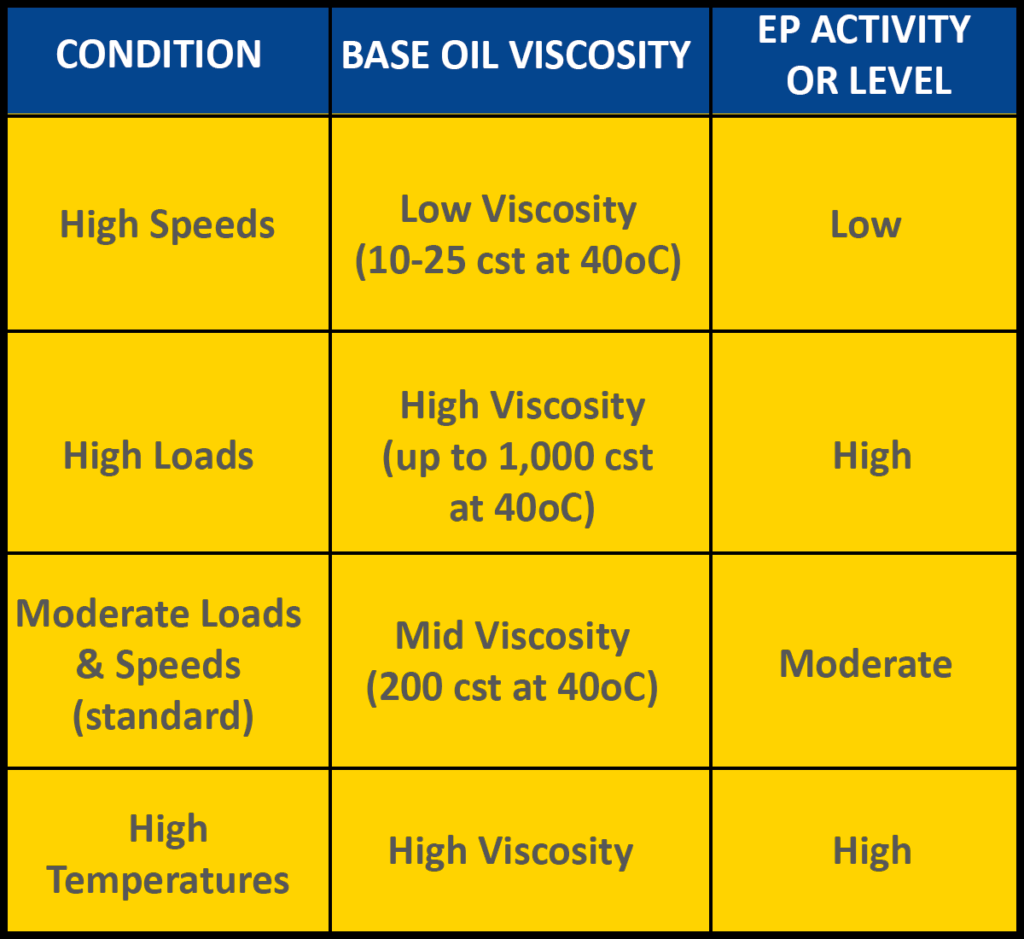

Viscosity is the resistance of a fluid to flow, which is crucial for lubricant performance by determining its ability to coat and protect machinery surfaces from friction and wear. Measured in centistoke, usually at 40°C, ISO-standardized lubricant selection defines viscosity grades for different operational conditions.

Viscosity is crucial as it affects the lubricant’s film strength and efficiency in reducing friction between moving parts. High viscosity shows thick oil, while low viscosity shows thin oil.

Consistency

The consistency or working stability of grease refers to its state of maintaining its thickness and properties after being subjected to mechanical pressure.

Dropping Point

The dropping point of grease shows the temperature at which it transitions from a solid to a semi-fluid state. This property is significant in applications where high temperatures are common. Grease with a higher dropping point maintains its structural integrity and lubricating properties under extreme heat, preventing it from dripping or running off critical components.

Water Resistance

The ability of grease to resist water washout and maintain its lubricating properties in wet or humid environments is crucial for protecting machinery from corrosion and wear. Water-resistant greases are formulated with additives that create a barrier against moisture intrusion, making them suitable for outdoor or submerged applications.

Thermal Stability

This refers to the grease’s ability to maintain structure and performance across various temperatures. In environments prone to temperature fluctuations, such as industrial machinery subjected to extreme heat or cold, thermal stability ensures consistent lubrication and protection against mechanical wear.

Oxidation and Corrosion Resistance

Grease that resists oxidation and corrosion helps prolong the lifespan of machinery by protecting metal surfaces from chemical degradation. Oxidation-resistant additives in grease prevent the formation of harmful acids and sludge, which can degrade lubricant performance and lead to equipment failure in harsh or chemically aggressive environments.

Load-carrying Additives

Extreme pressure additives enhance lubricants by improving their ability to endure high loads, reduce wear, and minimize friction between metal surfaces. They form a protective film that shields against damage in high-pressure applications like heavy machinery, gears, and bearings. These additives chemically react with metal surfaces to create a sacrificial layer, preventing metal-to-metal contact and potential failure under extreme conditions.

Types of Base Oils Used in Grease

Grease lubricants primarily comprise oil trapped in a thickener, which gives it density or stiffness. Base oils are mineral or synthetic, with mineral oils commonly used except in extreme temperatures where synthetics are preferred. The oil and additives provide lubrication, not the thickener, although the thickener influences grease performance and suitability.

Mineral Base Oils: Derived from crude oil, mineral base oils are economical and widely used but have limitations like a low viscosity index and poor thermal stability. They are classified by refining process and viscosity as paraffinic, naphthenic, or aromatic.

Synthetic Lubricants: Synthetic base oils are primarily derived from low molecular weight hydrocarbons. Synthetic lubricants are manmade with tailored properties such as high viscosity index and excellent thermal stability. Synthetic base oils enhance machine performance in various applications. Chemical structures such as PAOs (polyalphaolefin), PAGs (polyalkylene glycols), or esters (diester, polyol ester, phosphate ester) are commonly used in synthetic lubricants.

Bio-based Base Oils: Derived from renewable sources like vegetable oils or animal fats, bio-based oils offer biodegradability and environmental benefits. Feedstock classifies them as vegetable oil-based or animal fat-based.

Choose Fluid Solutions for Your Grease and Lubrication Needs

Fluid Solutions offer a wide range of greases and lubricants. For 16 years, we’ve provided superior lubrication solutions to manufacturing, steel production, sugar mills, coconut oil mills, and the food and beverage sectors in the Philippines.

Fluid Solutions is 100% committed to enhancing productivity and prolonging component life with our lubrication solutions, delivering goods and services quickly, conducting business with honesty and transparency, responding to client communications within 24 hours, and providing excellent pre- and post-sale services.

Contact us today at (02) 8370 5928 / (0917) 894 9156 or email inquiry@fluidsolutions.com.ph for personalized guidance on selecting suitable lubricants for your business. You can also reach us via our official website or social media pages for any grease and lubrication concerns.